|

Pulsed-laser ablation

: thin films

Supported by :

|

|

Description

We are using a pulsed-laser ablation deposition (PLD) system to prepare

high quality thin films which are used in a wide series of studies exploring

the most fundamental questions as the mechanism of high temperature superconductivity,

but also designing new devices on various lengthscales. These high quality

films will be used for fundamental and applied research, a major part within

the infrastructure already in place at the QML and IMSI (in particular

the equipment used for nanolithography at the Electrical Engineering Dept

at the Université de Sherbrooke), but also through external collaborations.

Pulsed laser deposition has been under strong development since the

discovery of high temperature superconductors. This technique is now used

in the fabrication and study of oxide-based devices, for example the spin-polarized

injection devices composed of superconducting (YBCO) and ferromagnetic

(LSMO) components. In our group, we use for example PLD for optimisation

of composition of the electron-doped cuprates. Since they possess a very

narrow range of Ce concentrations exhibiting superconductivity (Tc

is peaked around x = 0.15), it makes them more sensitive to inhomogeneities

than the hole-doped cuprates. To study their physical properties, we use

PLD to target a very accurate cerium content. It is then possible to get

c-axis oriented thin films even in the concentration range from x = 0.12

to x = 0.15 where Tc goes from 0 to 22K (in PCCO).

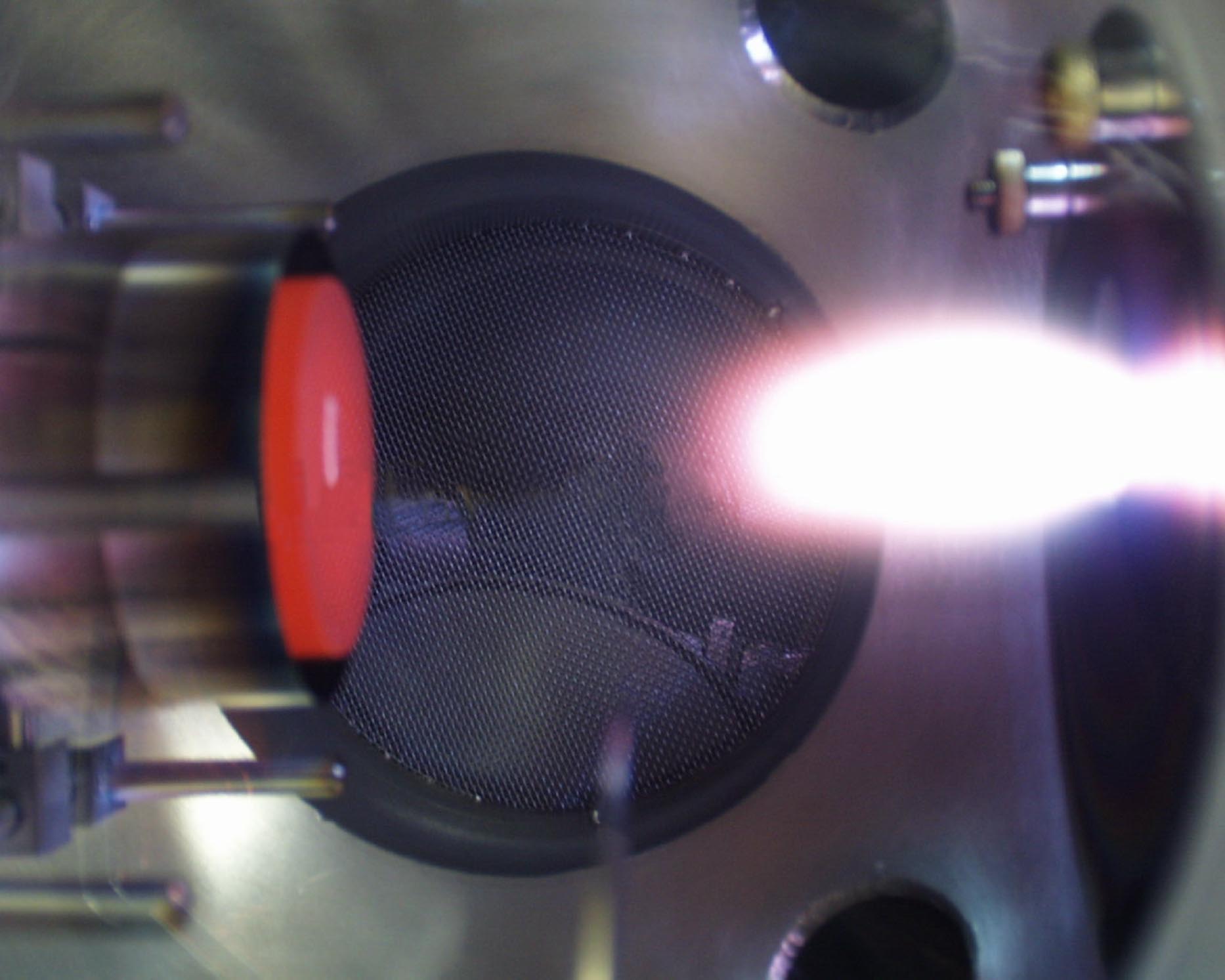

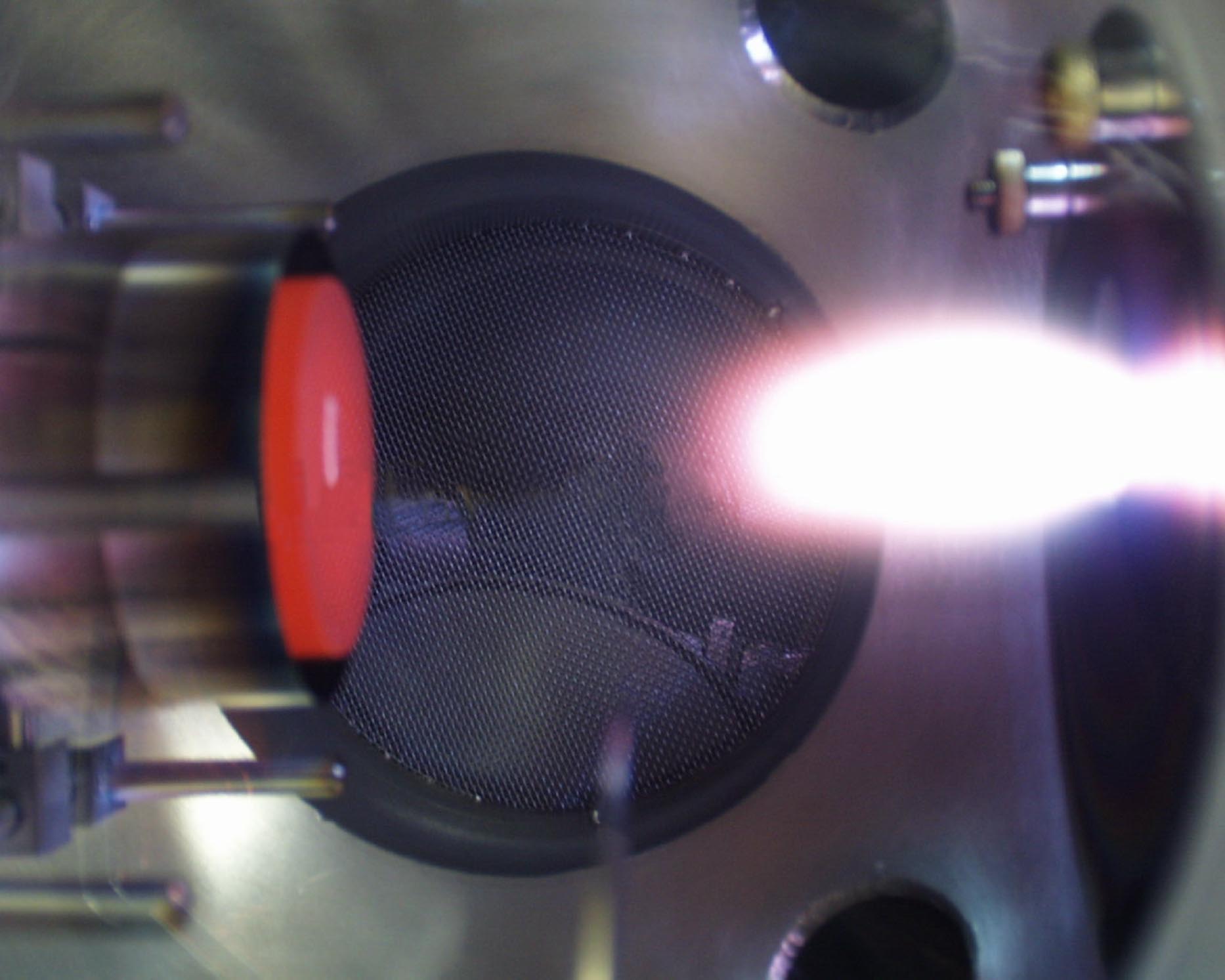

Principle of operation

A target made of polycrystalline materials (most often with the desired

stoichiometry) is hit by a high energy pulsed laser beam (KrF excimer laser

: typical energy density at the target of 2 J/cm2 with typical

repetition rate of 5 to 10 Hz). Materials is ablated from the target, and

sputtered toward a hot substrates. The various ions, with high energy and

high mobilities for such high temperatures, deposit on the substrate and

form the desired crystal structure, after optimisation of several parameters

: temperature, nature and position of substrate, type of atmosphere and

its pressure during deposition, energy density of laser, post-annealing

treatments (time and type),... The final goal, usually, is to obtain epitaxial

thin films, having preferred orientation and most of their properties very

close to the bulk (crystalline) ones. This is achieved after a complete

exploration of the abovementoned growth parameters. A very active area

at the present time is the exploration of the effect of artificial pressure

(from the substrate) onto the properties of the materials deposited.

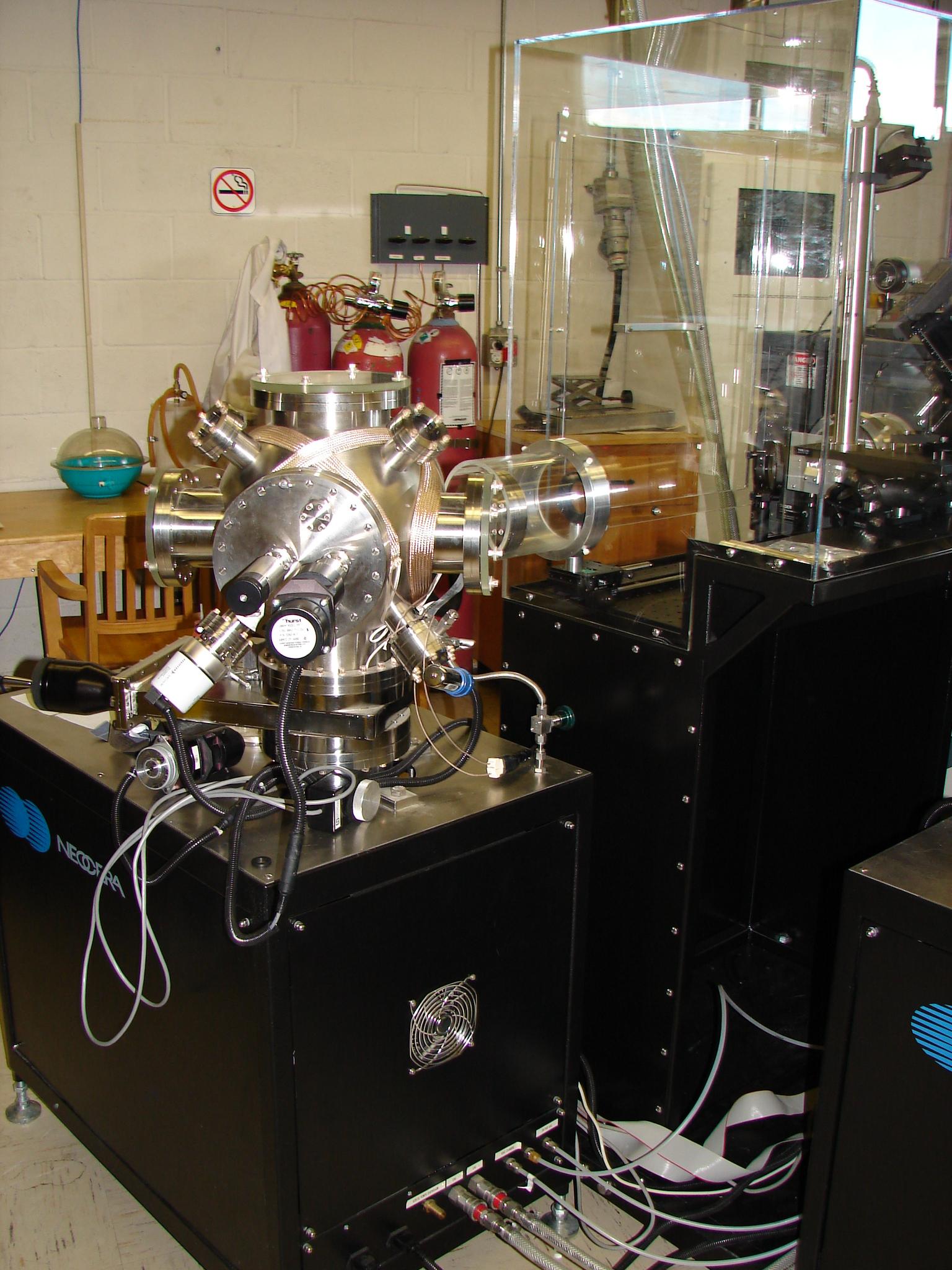

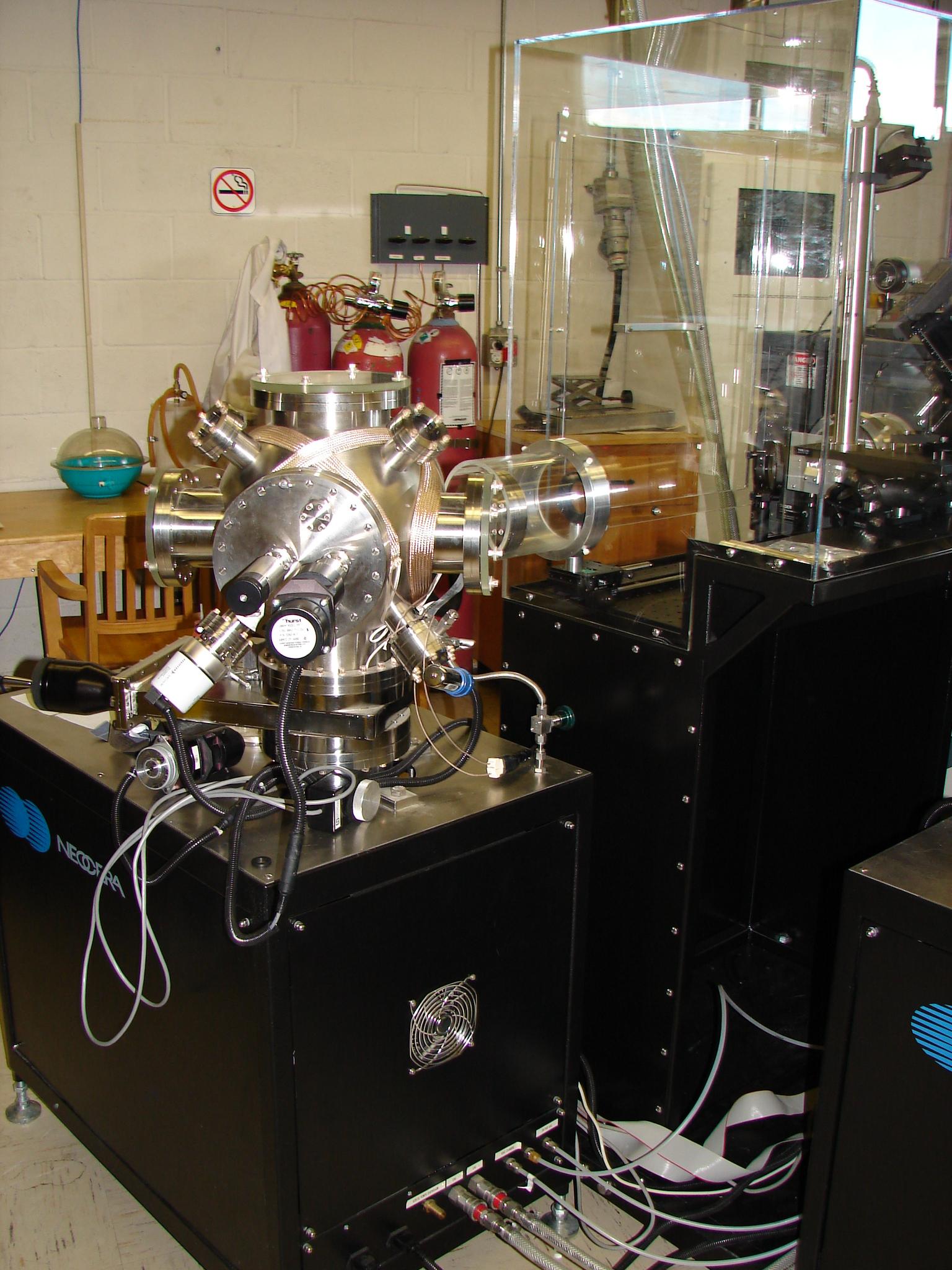

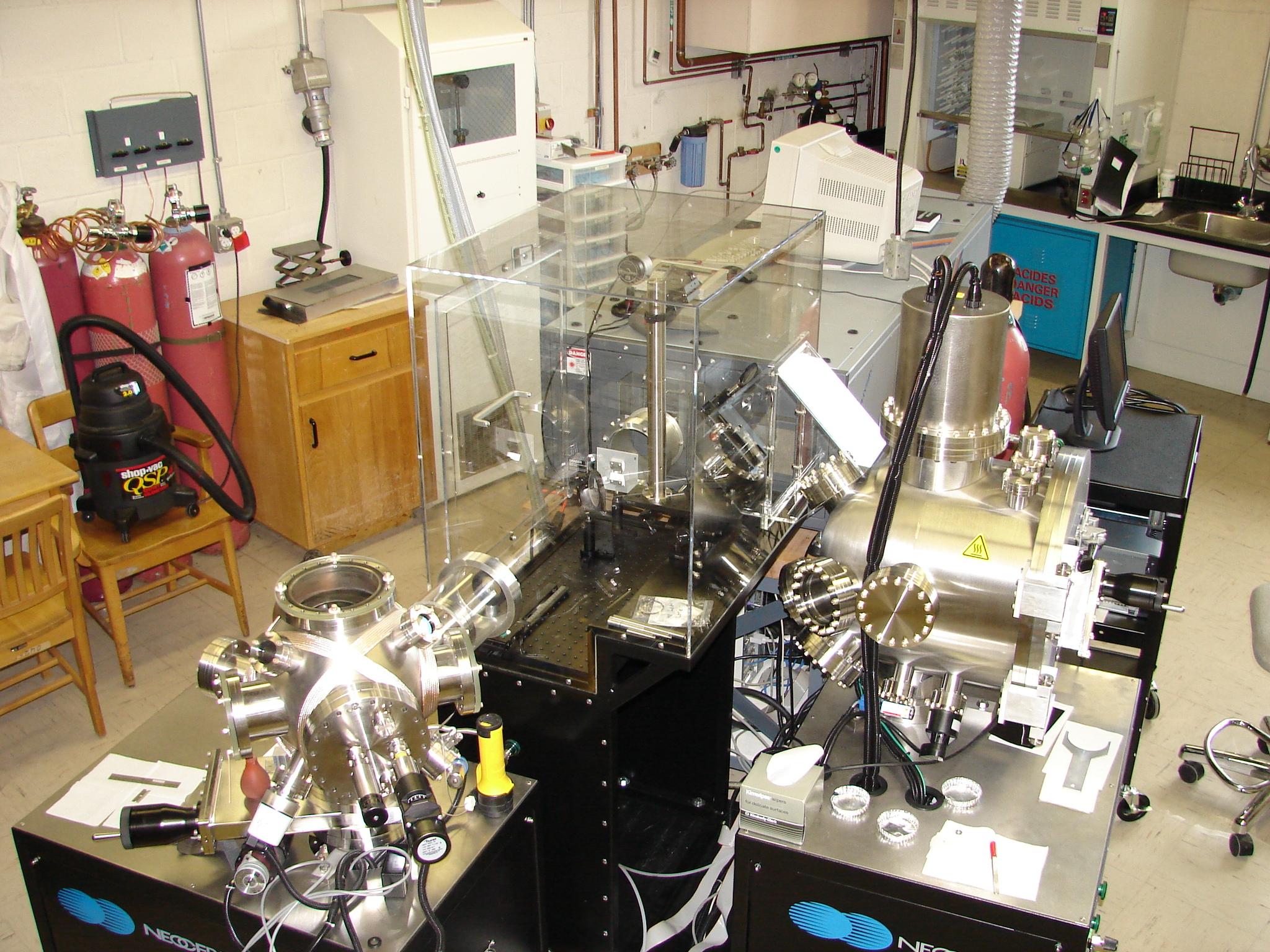

PLD system (U.

de Sherbrooke)

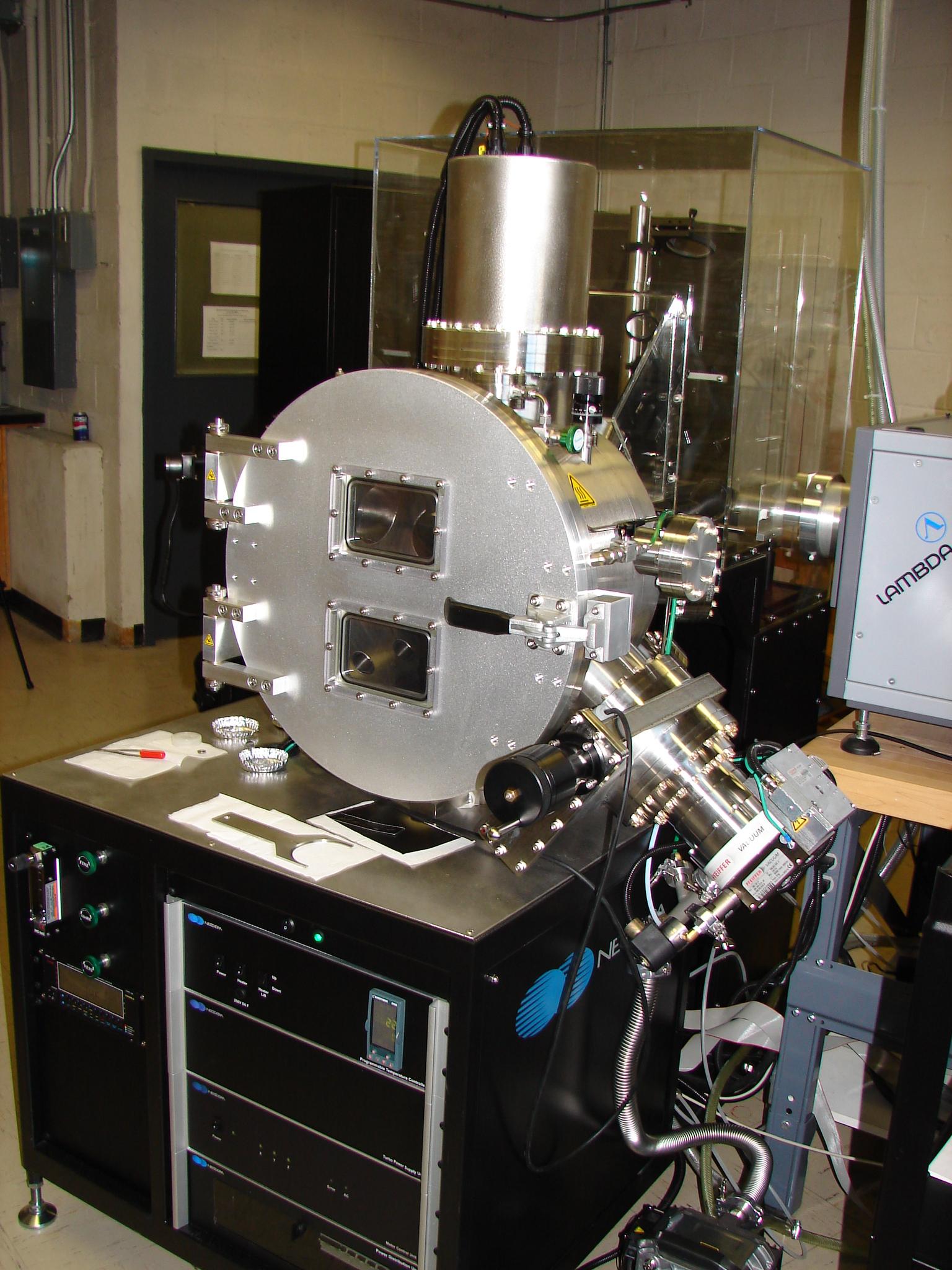

PLD system (U.

de Sherbrooke)

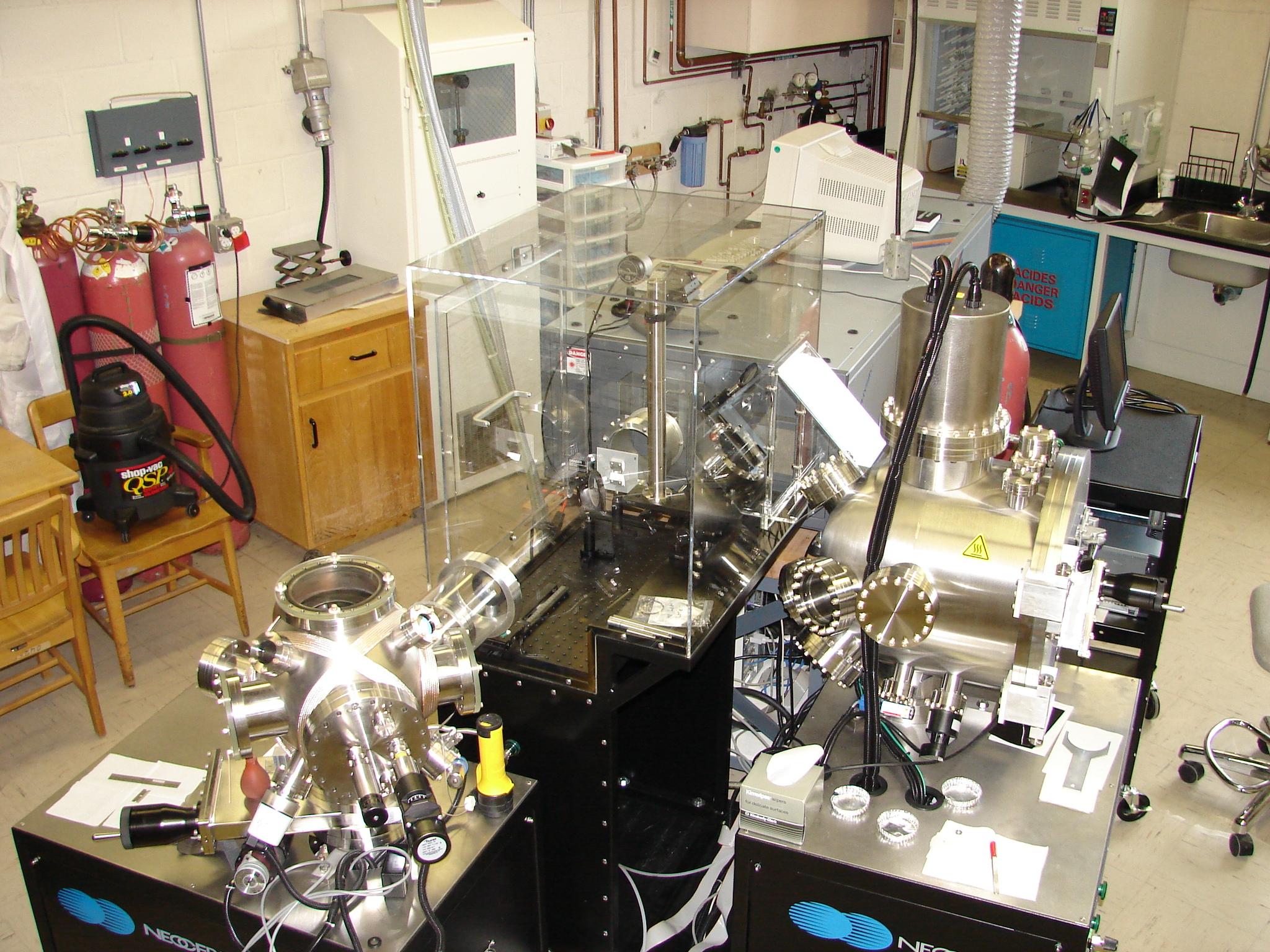

Our laboratory

Our thin film growth laboratory includes :

1) A pulsed laser from Lambda Physik (LPX 305)

Maximum energy per pulse : 1.4 J

Pulse width : 20 ns

Maximum repetition rate : 50 Hz

|

|

2) A conventional 12" diameter spherical chamber (Neocera)

Max substrate temperature : 950oC

Gas : O2, N2O, Ar

Max Substrate size : 1 cm2

|

|

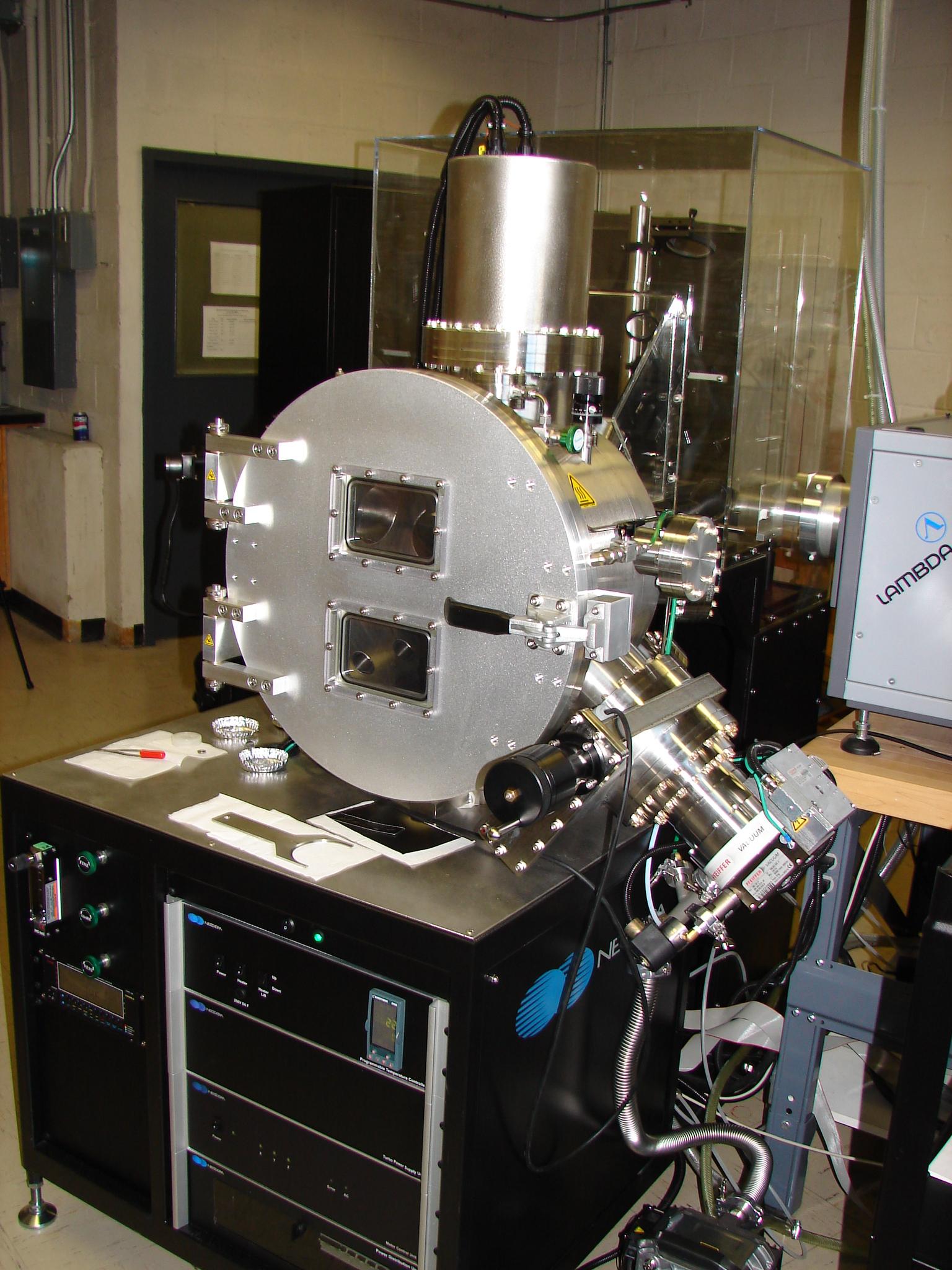

3) A custom 18" diameter semi-spherical chamber with hinged front

door (Neocera)

Max substrate temperature : 950oC

Gas : O2, N2O, Ar

Max Substrate size : ~3x3 cm2 (2" diameter)

|

|

This laboratory is part of the Réseau québécois

sur les matériaux de pointe (RQMP)

, the Quantum Materials Laboratory (QML) and the Institut des

matériaux et systèmes intelligents (IMSI).

Last modified : 30 March 2006 (P.F.)

PLD system (U.

de Sherbrooke)

PLD system (U.

de Sherbrooke)